Flap discs are versatile: they can grind, blend and finish. They are also lightweight, easy to manoeuvre, and require less change over time. When performing a job, many operators prefer flap discs over grinding wheels due to lower vibration and noise levels. Plus, they offer cooler cutting with minimal scratching. For instance, grinding wheels have to be discarded even after a small area of abrasive is worn out. Comparatively, flap discs remain useful even after the flaps erode, which results in a longer operating life. Compared to a flap disc, grinding wheels are cheaper on a unit cost basis. However, if you consider the versatility, durability and ease of use provided by flap discs, they are more cost-effective in the long run.

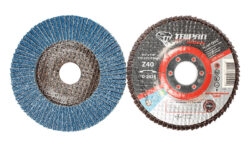

115mm x 40g SMT325 Flap Discs (SMT618)

£0.00

Flap discs are versatile: they can grind, blend and finish. They are also lightweight, easy to manoeuvre, and require less change over time. When performing a job, many operators prefer flap discs over grinding wheels due to lower vibration and noise levels. Plus, they offer cooler cutting with minimal scratching. For instance, grinding wheels have to be discarded even after a small area of abrasive is worn out. Comparatively, flap discs remain useful even after the flaps erode, which results in a longer operating life. Compared to a flap disc, grinding wheels are cheaper on a unit cost basis. However, if you consider the versatility, durability and ease of use provided by flap discs, they are more cost-effective in the long run.

Have a question about this product? Call us now on 01234 345111 or email [email protected]

Additional information

| Product Type | |

|---|---|

| Brand | Klingspor |

| Family | 115mm dia, SMT325 |